Coil Width: 300mm

Outside Dia.: 1.200 kg

Capacity:2.000

Power: non-motorized brake type

TermalKapasite

Çalışma Basıncı

Mevcut Yakıt

Mevcut Endüstriler

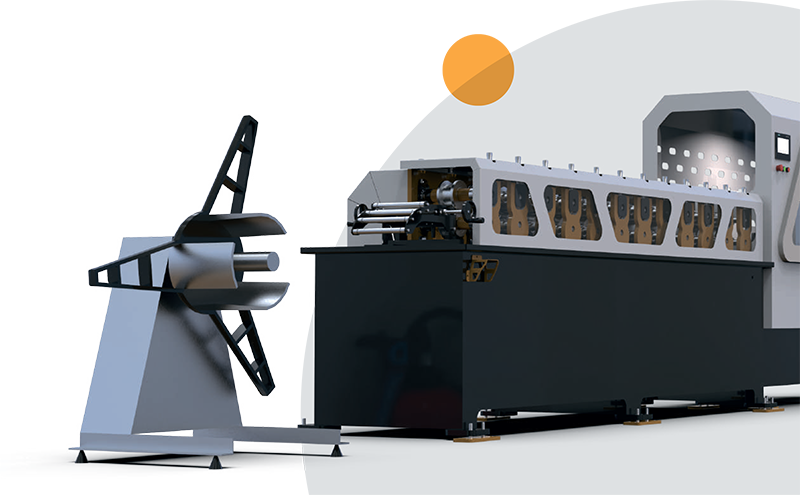

We can develop lines for cable channel production that can automatically adjust variables such as base width and edge height, enabling successful production at desired speeds. Depending on the thickness and quality of the sheet metal, we can set up flexible production lines.

With the cable tray manufacturing machine, you can produce sheet metal cable channels and cable ladders in the desired sizes.

Our company can produce cable channel machines with various features, as well as roll forming and shaping lines for sheet metal processing. We offer quick solutions for adjusting speed within the line and transitioning between products easily.

Technical Specifications

Cable Tray Manufacturing Line cable tray from strip or coil metal designed for the production of ducts. Automation technology precise and serial production is ensured thanks to the high quality end product is obtained.

Let's find the product that best suits you!